NextSpot 600 Phased Array Ultrasonic Spot Weld Tester

The NextSpot 600 phased array ultrasonic spot weld tester will handle all your spot weld NDT needs, whether it is in production lines or in field environments. The unit is constructed with an one piece all aluminum housing, that is both rugged and lightweight, with a weather protected rubber coating on the outside. Using patented technologies, backed by years of R&D in the NDT industry, NextSpot 600 can produce real-time imaging with auto-detection on spot weld flaws both quickly and accurately.

In today’s ever increasing competitiveness in the automotive manufacturing segment, NextSpot 600 with its easy-to-use and its powerful feature interface can save valuable time and increase productivity.

Request a Quote

We pride ourselves in providing fast deliveries. However inventory changes rapidly and on occasion some items may not be in stock. If you require an expedited shipment, please contact us via e-mail or call our office to confirm availability of an item. *Nominal lead times vary by product.

Key Features and Benefits

NextSpot 600 is constructed with an all aluminum alloy shell with 360° shielding. It adopts a one-piece aluminum alloy with rubber coating that makes it rugged, lightweight, and compact. The unit is also weather protected and stress tested so that It can operate from -10°C ~ 50°C. Weighing at only 3 kg, NextSpot 600 is both portable and reliable, especially for conducting field testing.

NextSpot 600 uses the ARM processor, which know for energy efficient, and along with a fanless design, a fully charged unit can perform 12 hours of normal operation, and requires only 3 hours for a complete recharge.

Testing in the field are often conducted in harsh environments where visibility may be poor and requires having to wear gloves. The NextSpot 600’s 10.4 inch full touchscreen with XGA wide-angle viewing help address these common issues all while giving you the most accurate visual results and feedback.

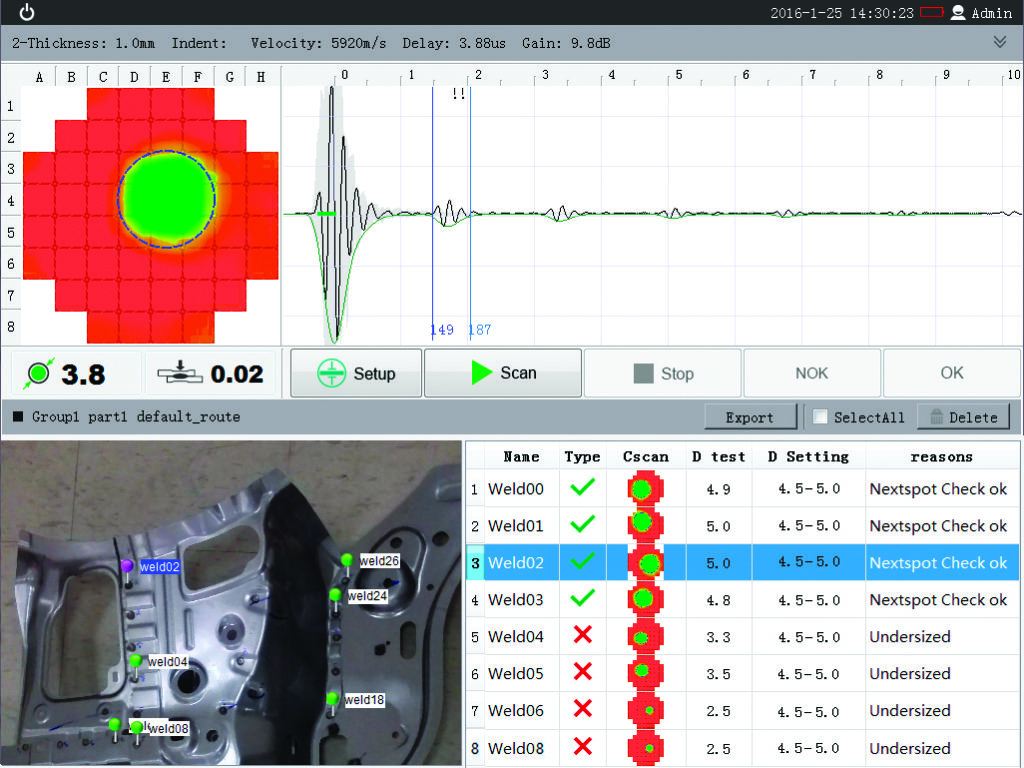

By adopting a parallel 64 channel design, 1MHz-25 MHz analog bandwidth, and 12 bits DSP, it gives NextSpot 600 the most accurate measurement of welding nuggets and indentations. Furthermore, the results are all visual and can be immediately determined whether the results are passed or failed.

NextSpot 600 can provide A/C – scan and real-time display on spot weld. NextSpot 600 can support single element probe testing, PA imaging testing as well as various nonultrasonic methods, data capture, chisel inspection, visual inspection, and many more.

At the heart of the device is our NextSoft Analyser user interface that we build from the ground up. Built on top of the Linux OS platform, it provides a safe, reliable and stable platform for our software system. Boasting a 10 seconds startup time, it can be quickly and easily setup to perform real-time image scanning on spot welds.

Specifications

Housing

Overall Dimensions –287 mm × 267 mm × 67 mm (11.3 in. × 10.6 in. × 2.6 in.)

Weight –3.5 kg (7.7 lb) with Battery

IP –IP 54

Control Device –Remote Control, Touch Screen

Probe –D-sub 68 – Matrix

Power Socket –5.5-2.5 mm DC Socket

Environmental

Operating Temperature –-10°C to 50°C (14°F to 122°F)

Storage Temperature –-20°C to 60°C (-4°F to 140°F) with Battery; -20°C to 70°C (-4°F to 158°F) without Battery

Relative Humidity –Max. 70% RH at 45°C Non-condensing

Display

Display Size –26.4 cm (10.4 in.)

Resolution –1024 x 768

Brightness –600 cd/m

Viewing angles –Horizontal: –89° to 89° Vertical: –89° to 89°

Probe –D-sub 68 – Matrix

Type –TFT LCD

Power Supply

Battery Type –Smart Li-ion Battery

Number of Batteries –One

Battery Life –Approximately 12 Hours Under Normal Operating Conditions

Power Supply Unit –100-240 V AC, 47-63 Hz, 1.45 A

PRF –8K Hz (No Continuous Pulse Series)

Ultrasound Specs

渠道/元素的数量64 Channels / 52 Elements

Voltage –50 V

Pulse Shape –Negative Square Wave

Initial Pulse Rise Time –<2.5 ns

Damping –50 ohm

Thickness Measuring Range –0.5-9 mm

Velocity Range –2000-8000 m/s

Probe Delay –2-8 us

Frequency (Center Frequency) –1 Mhz – 25 Mhz (16 MHz)

Gain –40 dB

Sampling –12 bit 100 MSPS