MIZ-21C Eddy Current Tester w/ Array Capability

The Zetec MIZ-21C is the most advanced handheld instrument with surface array capabilities. The truly affordable MIZ-21C is ideal for aerospace, oil & gas, manufacturing and power generation applications. Its ergonomic design, long battery life and intuitive touchscreen mean you can inspect more areas faster than ever without fatigue. The MIZ-21C is compatible with a wide range of probes and scanners and comes in three models to meet your unique inspection needs and budget.

Request a Quote

We pride ourselves in providing fast deliveries. However inventory changes rapidly and on occasion some items may not be in stock. If you require an expedited shipment, please contact us via e-mail or call our office to confirm availability of an item. *Nominal lead times vary by product.

The Zetec MIZ-21C is packed with features for an inspection advantage.

Surface array in a handheld

- Cost-effective, highly portable solution that delivers significant advantages over Liquid Penetrant Testing (PT) and Magnetic Particle Testing (MT)

Increase uptime, wherever you go

- Features a minimum eight-hour battery life so users can operate the unit for an entire shift without recharging

人体工学设计

- Small, lightweight and comfortable to handle in tight spaces. MIZ-21C minimizes arm fatigue common with other portable instruments

Intuitive touchscreen

- Quickly rotate, zoom and pan using the two finger capacitive display

- Onscreen keyboard further increases user efficiency.

Universal symbol buttons & multi-language software

- One model for worldwide use and deployment

- Universal symbol buttons handle all functions and are ideal for gloved inspections

Flexible connectivity

- Interface and transfer files through USB, Wi-Fi, and Bluetooth technology

Built for demanding environments

- Fully sealed and temperature rated for most outdoor conditions

- Drop and vibration tested for rugged use

Highly versatile

- Standard ¼-20 Fitting to connect to thousands of off-the-shelf accessories for expanded functionality

- Removable cover with adjustable hand straps and stand is included

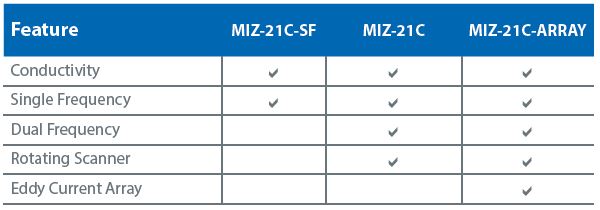

Three models available

- MIZ-21C-SF: Single Frequency, Conductivity

- MIZ-21C: Dual Frequency, Conductivity, Rotating Scanner

- MIZ-21C-Array: Dual Frequency, Conductivity, Rotating Scanner, ECA

Adaptable to Meet Your Needs

MIZ-21C offers a range of accessories designed to meet your specific inspection needs.

ZM-5 Rotating Scanner for Small Diameter Holes.

Zetec’sZM-5 High-Speed Scanneris a convenient handheld tool designed for rapid and thorough inspection of small diameter holes, such as bolt hole and fastener holes. With an ergonomic design, the ZM-5 enables inspection of the hardest to reach areas. A rotating transformer couples the eddy current signals for an improved operating life over conventional slip rings. The ZM-5 uses a quick-disconnect cable design for easy replacement. Through adapters the MIZ-21C can drive other manufacturers’ rotating scanners.

Surf-X™ Array Probes for Faster Flaw Detection

Introducing the Zetec Surf-X line of surface array probes. Featuring a unique flexible circuit design and proprietary X-Probe™ technology, Surf-X array probes can lower total cost of ownership while providing excellent data quality as well as faster, safer inspections when compared with other inspection methods.

Inspecting Corrosion or Cracking in Pipes, Pressure Vessels, or Tanks

Surf-X灵活的阵列探测器可以符合gradual changes in the geometry of pipes, pressure vessels, or tanks to detect surface and sub-surface flaws in a variety of materials including aluminum and stainless steel. Corrosion is a common flaw in non-pressurized components, while stress corrosion cracking is common in components subjected to sustained tensile stress in a corrosive environment. The Surf-X array probe can easily detect the locations of both types of defects using the high precision embedded encoder to track position.

Assessing and Sizing Cracks in Raised Welds and Friction Stir Welds

Surf-X flexible array probe can also conform to geometry changes associated with raised welds to simultaneously inspect for axial and transverse cracking in the weld cap, toe, and heat-affected zones. Surf-X array probes use position indicators on the probe to help with alignment to ensure the entire area of interest is inspected. The flexible nature of the Surf-X array probe allows for the inspection of flat surfaces including friction stir welds. The long-life wear surface has been tested to 10,000 ft, and is an inexpensive field replaceable component.